Factory Desktop Application

Case study: Custom Electron desktop app for IoT device manufacturing. 10x faster processing, 99.5% quality rate, with barcode scanning and ERP integration.

Project Overview

The manufacturing client was using a combination of paper forms and spreadsheets to track IoT device assembly. This manual process was slow, error-prone, and provided no real-time visibility into production status.

We built a custom desktop application that guides operators through the assembly process, automatically captures data, and integrates with the factory’s existing systems.

Technical Implementation

The application was designed for the manufacturing environment:

- Cross-Platform: Built with Electron to run on Windows workstations

- Offline-First: Local SQLite database with background sync when connected

- Hardware Integration: USB serial communication for device programming

- Barcode Scanning: Integration with industrial barcode scanners

Production Benefits

The system transformed factory floor operations:

- Guided Workflows: Step-by-step interfaces with validation at each stage

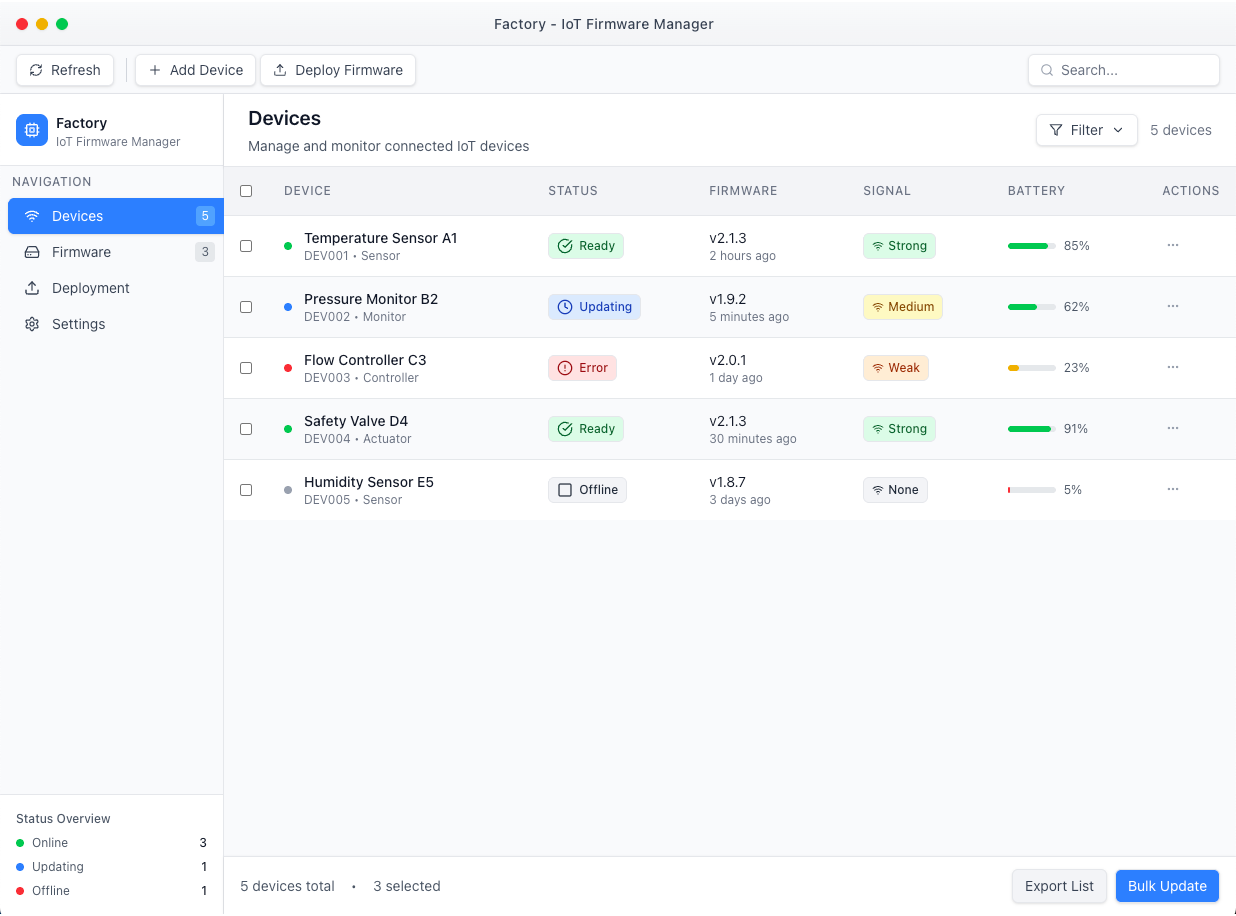

- Real-Time Tracking: Live production dashboards and inventory visibility

- Quality Assurance: Automated testing sequences with pass/fail logging

- ERP Integration: Seamless sync with existing enterprise systems

!Challenges

- Complex hardware integration requirements

- Offline-first operation needs

- Strict quality control requirements

- Training non-technical operators

- Integration with existing ERP systems

Solutions

- Built cross-platform desktop app with Electron

- Implemented local SQLite database with sync

- Created guided workflow interface

- Integrated barcode and USB serial devices

- Built API bridge for ERP integration

Results & Impact

10x faster device processing

99.5% first-pass quality rate

Eliminated paper-based tracking

Reduced training time to 1 hour

Real-time production visibility

Let's Build Something

Amazing Together

Let's discuss how we can help you achieve similar results.